ICON BI-COMPONENT PU/VIBRAM® RUBBER HRO FIRE & ICE

The bi-component sole made of polyurethane and HRO FIRE & ICE VIBRAM® rubber offers maximum support and stability even on challenging surfaces. The F&I compound, developed over years by VIBRAM®, is engineered to perform under extreme conditions, from -20°C to +300°C in contact heat. It remains compact and efficient despite high temperatures (FIRE) due to the absence of adhesives, while maintaining flexibility at very low temperatures (ICE), ensuring it remains soft and provides excellent grip on icy and frozen surfaces. Designed for use with crampons, the sole features small treads in the contact area to enhance grip on ladder rungs. Resistant to oils and hydrocarbons, it has been tested in SATRA laboratories to resist slipping on metal grates (Kennedy Grating Test) and wooden boards (Scaffold Board Test).

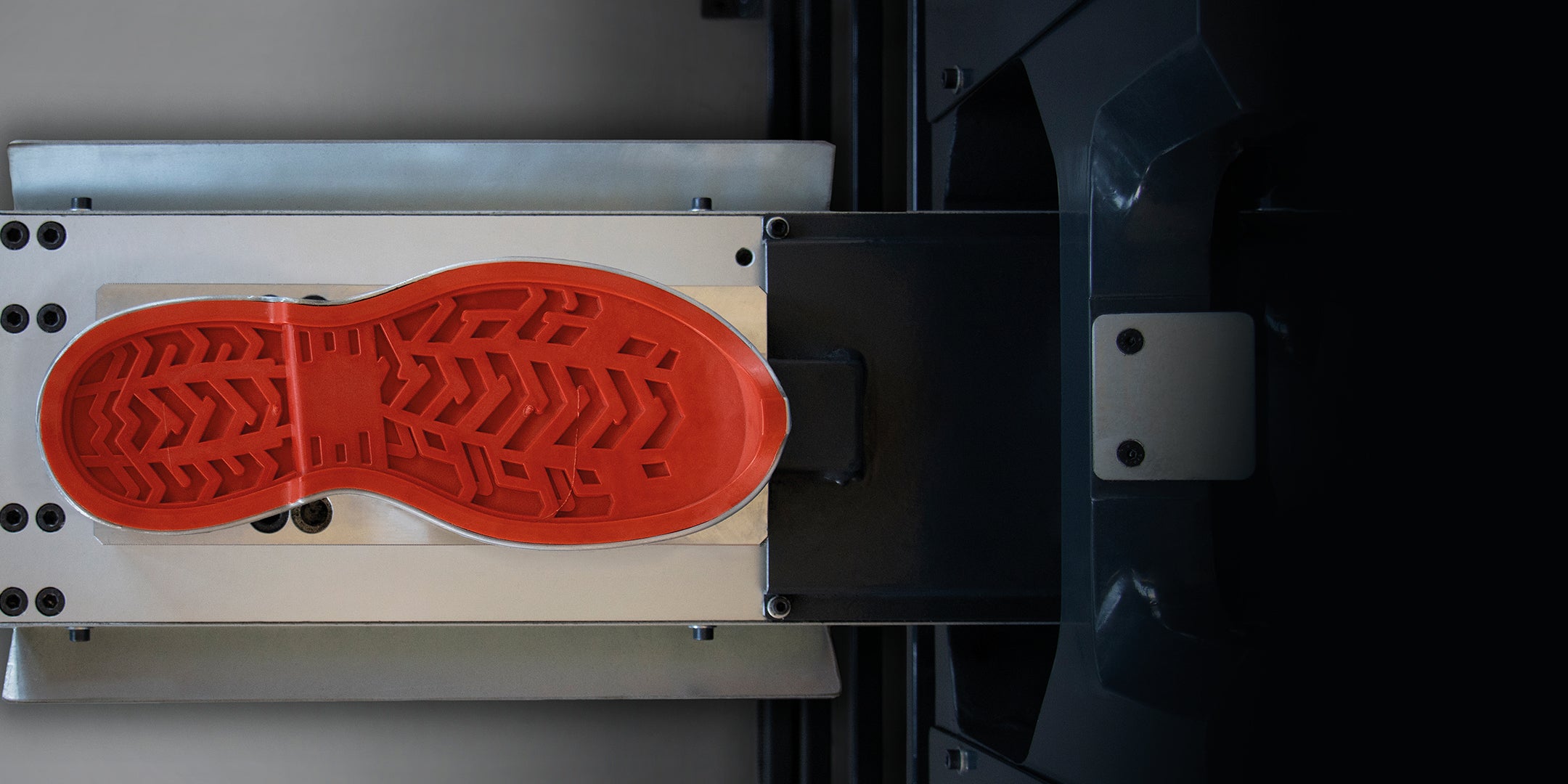

ICON BI-COMPONENT PU/VIBRAM® RUBBER HRO

The Vibram® rubber compound combined with the polyurethane midsole ensures lightness, flexibility, and high abrasion resistance. The antistatic properties and HRO contact heat resistance (up to 300°C for 60 seconds) make it an ideal high-performance outsole for industrial environments. It features an antistatic design with a sporty and dynamic appearance.

TYRE BI-COMPONENT PU/VIBRAM® RUBBER HRO

The Vibram® rubber compound combined with the polyurethane midsole ensures lightness, flexibility, and high abrasion resistance. The antistatic properties and HRO contact heat resistance (up to 300°C for 60 seconds) make it an ideal high-performance outsole for industrial environments. It features an antistatic design with a sporty and dynamic appearance.

HYBRID BI-COMPONENT PU/RUBBER HRO

The bi-component polyurethane and rubber sole is designed to provide maximum performance in terms of safety and comfort. It offers excellent resistance to oils, hydrocarbons, and slipping. Resistant to HRO contact heat (up to 300°C for 60 seconds) in accordance with European standards, the sole has been tested in SATRA laboratories for slip resistance on metal grates (Kennedy Grating Test) and wooden boards (Scaffold Board Test).

BUBBLE TRI-COMPONENT PU/TPU ESD WITH “PLUG-IN” SYSTEM

This tri-component sole features an antistatic TPU outsole with ESD characteristics, a translucent TPU casing, and a patented PLUG-IN mechanism. The design allows for the insertion of a cushioning pad made of BUBBLE material, which includes high-energy-return thermoplastic elastomer spheres embedded within an absorbing polymer matrix. The system is engineered to ensure optimal synergy between the sole components and the BUBBLE cushioning pad, achieved through the dispersion of spherical thermoplastic functionalized charges within a polymeric matrix.

REBOUND BI-COMPONENT PU/TPU ESD

The bi-component sole features an antistatic TPU outsole with ESD characteristics, offering ultra-lightweight, high flexibility, and a functional cushioning heel design. The highly antistatic TPU outsole is engineered to exceed the requirements of EN ISO 20345:2022, ensuring reliable grip throughout all phases of walking. Its uniformly distributed contact surface makes it versatile for various types of terrain. The polyurethane midsole is designed with functional grooves of varying depths to provide comfort and effective energy absorption in the heel area.

TYRE BICOMPONENT PU/TPU

The TYRE sole features a comfortable PU midsole and a TPU outsole. It is resistant to contact heat up to 120°C. TPU is an exceptionally durable thermoplastic material known for its mechanical and aesthetic properties. It resists oxidation, offers superior flexibility compared to other thermoplastics, and has excellent abrasion resistance. The unique formulation of TYRE TPU soles ensures maximum flexibility where the shoe bends, such as when kneeling, providing enhanced freedom of movement.

ICON DUAL DENSITY PU/PU

The ICON sole features a dual density polyurethane design, engineered to deliver excellent performance across various terrains, from wet to dry conditions. Its enhanced tread patterns and widespread channels facilitate the discharge of liquids and debris, improving stability. The sole is antistatic and includes a shock-absorbing heel cell. It has been tested in SATRA laboratories for slip resistance on metal (Kennedy Grating Test) and wooden (Scaffold Board Test) surfaces.

HYBRID DUAL DENSITY PU/PU

The HYBRID sole is made from dual-density polyurethane and utilizes the Esolight system to ensure maximum support and stability. Its tread pattern features a unique design to provide excellent traction on all types of terrain. It is slip-resistant in accordance with the latest EN 20345:2022 standard, thanks to the extensive contact area in the forefoot. The “shell” heel design offers cushioning during walking, promoting a beneficial and consistent reduction in fatigue.

TYRE BIDENSITY PU/PU

The TYRE sole is a lightweight, sporty dual-density polyurethane design. Crafted using Smart Injection technology, it features a tread with exceptional flexibility and durability. This sole ensures excellent slip resistance and high abrasion resistance.

SOLID BIDENSITY PU/PU

The SOLID sole features a dual-density design, combining lightness and flexibility with Esolight 1.0 and 2.0 polyurethane compounds. The midsole, made of low-density microcells, enhances energy absorption, while the high-density outsole provides increased durability and slip resistance.